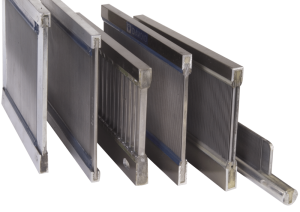

Textile reed wire, also known as reed wire or weaving wire, is a type of wire used in the manufacturing of textile reeds. A textile reed is an essential component of weaving looms, used to separate and space the warp threads during the weaving process. Reed wires are inserted into the reed’s metal or wooden frame, forming a series of parallel and evenly spaced wire teeth or dents.

Here are some key characteristics and uses of textile reed wire:

- Material: Reed wire is typically made from stainless steel or carbon steel. Stainless steel reed wire is preferred for its corrosion resistance and durability, while carbon steel reed wire is more affordable and suitable for less demanding applications.

- Strength and flexibility: Reed wire needs to be strong and flexible to withstand the tension and movement of the warp threads during weaving. It should be able to maintain its shape and resist deformation over time.

- Smooth surface: Reed wire is usually polished or coated to ensure a smooth surface. This helps prevent snagging or damaging the delicate warp threads during the weaving process.

- Precision spacing: The wire teeth or dents of a textile reed need to be precisely spaced to maintain the desired fabric weave structure. Reed wire is manufactured with consistent spacing to ensure the accurate positioning and separation of warp threads during weaving.

- Durability: Textile reed wire is designed to withstand the repetitive and abrasive motion of the warp threads. It should be durable enough to endure prolonged use without significant wear or damage.

Textile reed wire is primarily used in the textile industry for weaving various types of fabrics. The reed wire is mounted onto the reed’s frame, which is attached to the loom. During the weaving process, the warp threads are threaded through the dents of the reed wire, which separates and spaces them evenly to create the desired fabric structure. The reed wire helps ensure precise alignment and tension of the warp threads, resulting in a well-formed and consistent fabric weave.

The selection of the appropriate textile reed wire depends on factors such as the type of fabric being woven, the desired weave pattern, and the operating conditions of the loom. Manufacturers typically offer a range of reed wire options to accommodate different weaving requirements.

Overall, textile reed wire plays a vital role in the weaving process, enabling the creation of quality fabrics with consistent and accurate patterns.